R01

© WIAC Ltd 2017. WIAC Ltd, Registered Office: Stoneygate House, 2 Greenfield Road, Holmfirth, Yorkshire,HD9 2JT UK

Reg: 6664171 VAT No: GB939454778

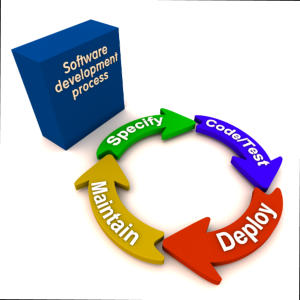

Full Life Cycle

WIAC Ltd are capable of full life cycle activities for the design and development of PLC/PAC based control systems. WIAC Ltd. services include (but are not limited to) • Analysis • Specification • Design • Implementation • Commissioning and Maintenance of software and systems for the control of complex processes.

Systems Analysis and Design

WIAC Ltd. are capable of working with the client to produce their User Requirement Specification (URS) or Control and Operating Procedure (COP), or working with those documents to produce subsequent design specifications and documentation. WIAC Ltd. can produce a Functional Design Specification (FDS), Software Requirement Specification (SRS) or any design documentation required in either Microsoft Word or PDF format. A number of methods are used to specify the system from architecture drawings to timing diagrams and sequential function charts.

PLC/PAC, SCADA and HMI Development

WIAC Ltd have years of experience in modular, standards based software design for PLCs and HMIs. WIAC Ltd have extensive experience of client component libraries, such as Nestech Toolbox, Mars Standard Library as well as Thames Water and Scottish Water libraries, and supplier libraries such as Rockwell 's Plant PAx. IEC EN 61131 languages including ladder logic, structured text, function block diagram, statement list (instruction list) and sequential function chart.

Legacy Replacement

Many older PLCs have reached or are reaching end of life and are no longer supported by their manufacturer. Spare parts are difficult to come by and where they are available it is at a premium price. Many of these PLCs are currently running critical processes in a number of industries. Replacement of these systems with supportable systems is essential to maintain smooth operation and profitability of the affected processes. WIAC Ltd have worked on a number of legacy replacement projects, implemented on both a like for like and complete redesign basis. WIAC Ltd can advise on legacy replacement solutions to suit your requirements and your budget. Advising on software conversion issues, hardware replacement, wiring replacement and commissioning. We can also advise on risks and risk mitigation. We can also advise on the translation from obsolete programming languages to more modern languages.

Project Lead/Management

WIAC Ltd can supply technical leadership and project management to your teams or provide our own team to complete your project. Project management is carried out under recognised frameworks, such as Prince 2.

WIAC Ltd consultants have extensive experience in PLC

and SCADA based systems which include the following:-

•

Rockwell - PLC3, PLC5, SLC, Logix platform,

RSView/FTView

•

Semiens - S5, S7, WinCC, WinCC Flexible

•

Modicon

•

Omron

•

Mitsubishi

•

Intouch

•

Cimplicity/Fix

•

plus others

Training and Support

WIAC Ltd can offer tailored operator and maintenance training on our solutions, or more generalised training on some PLCs and SCADA packages. Training can be on site or web based. The development of self-paced, downloadable training solutions is also an option.

Test and Commissioning

WIAC Ltd are capable of the preparation of test documents and procedures for both site and factory acceptance testing, commissioning specifications and procedures or installation, operation and maintenance guides for the systems. We can also assist in the design of bespoke tests and simulations for novel applications. WIAC Ltd are experienced in the commissioning of control systems in a number of industries. From loop checking at a sewage treatment plant, to instrument commissioning at a gas storage facility. From VFD set up on a design facility test bed to weigh scale calibration at a food manufacturing plant.

Specialties include: Modular, standards based design, Library & Component

generation, Tool design - software tools for project execution.

© WIAC Ltd 2016.

WIAC Ltd,

Registered Office: Stoneygate House,

2 Greenfield Road, Holmfirth,

Yorkshire,HD9 2JT UK

Reg: 6664171 VAT No: GB939454778

Full Life Cycle

WIAC Ltd are capable of full life cycle activities for the design and development of PLC/PAC based control systems. WIAC Ltd. services include (but are not limited to) • Analysis • Specification • Design • Implementation • Commissioning and Maintenance of software and systems for the control of complex processes.

Systems Analysis and Design

WIAC Ltd. are capable of working with the client to produce their User Requirement Specification (URS) or Control and Operating Procedure (COP), or working with those documents to produce subsequent design specifications and documentation. WIAC Ltd. can produce a Functional Design Specification (FDS), Software Requirement Specification (SRS) or any design documentation required in either Microsoft Word or PDF format. A number of methods are used to specify the system from architecture drawings to timing diagrams and sequential function charts.

PLC/PAC, SCADA and HMI

Development

WIAC Ltd have years of experience in modular, standards based software design for PLCs and HMIs. WIAC Ltd have extensive experience of client component libraries, such as Nestech Toolbox, Mars Standard Library as well as Thames Water and Scottish Water libraries, and supplier libraries such as Rockwell 's Plant PAx. IEC EN 61131 languages including ladder logic, structured text, function block diagram, statement list (instruction list) and sequential function chart.

Legacy Replacement

Many older PLCs have reached or are reaching end of life and are no longer supported by their manufacturer. Spare parts are difficult to come by and where they are available it is at a premium price. Many of these PLCs are currently running critical processes in a number of industries. Replacement of these systems with supportable systems is essential to maintain smooth operation and profitability of the affected processes. WIAC Ltd have worked on a number of legacy replacement projects, implemented on both a like for like and complete redesign basis. WIAC Ltd can advise on legacy replacement solutions to suit your requirements and your budget. Advising on software conversion issues, hardware replacement, wiring replacement and commissioning. We can also advise on risks and risk mitigation. We can also advise on the translation from obsolete programming languages to more modern languages.

Project Lead/Management

WIAC Ltd can supply technical leadership and project management to your teams or provide our own team to complete your project. Project management is carried out under recognised frameworks, such as Prince 2.

Specialties include: Modular, standards based

design, Library & Component generation, Tool

design - software tools for project execution.

WIAC Ltd consultants have extensive

experience in PLC and SCADA based

systems which include the following:-

•

Rockwell - PLC3, PLC5, SLC, Logix

platform, RSView/FTView

•

Semiens - S5, S7, WinCC, WinCC

Flexible

•

Modicon

•

Omron

•

Mitsubishi

•

Intouch

•

Cimplicity/Fix

•

plus others

Training and Support

WIAC Ltd can offer tailored operator and maintenance training on our solutions, or more generalised training on some PLCs and SCADA packages. Training can be on site or web based. The development of self-paced, downloadable training solutions is also an option.Test and Commissioning

WIAC Ltd are capable of the preparation of test documents and procedures for both site and factory acceptance testing, commissioning specifications and procedures or installation, operation and maintenance guides for the systems. We can also assist in the design of bespoke tests and simulations for novel applications. WIAC Ltd are experienced in the commissioning of control systems in a number of industries. From loop checking at a sewage treatment plant, to instrument commissioning at a gas storage facility. From VFD set up on a design facility test bed to weigh scale calibration at a food manufacturing plant.